Jeep Jk Drive Shaft Torque Specs . Web apply some loctite to the nut threads and install the center nut on the flange. Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. For most of the screws they. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. Make sure you torque the nut to the specifications for the. All other drive shaft bolts. If nut is not tight enough you could have some vibration. We called the dealer and they said. Web with a torque wrench tighten the nut to 160 ft lbs of torque.

from azoffroading.com

If nut is not tight enough you could have some vibration. Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. All other drive shaft bolts. For most of the screws they. We called the dealer and they said. Web apply some loctite to the nut threads and install the center nut on the flange. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. Web with a torque wrench tighten the nut to 160 ft lbs of torque. Make sure you torque the nut to the specifications for the. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system.

Jeep JK Front and Rear Driveshaft

Jeep Jk Drive Shaft Torque Specs Web apply some loctite to the nut threads and install the center nut on the flange. We called the dealer and they said. If nut is not tight enough you could have some vibration. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. Web with a torque wrench tighten the nut to 160 ft lbs of torque. Web apply some loctite to the nut threads and install the center nut on the flange. Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. For most of the screws they. All other drive shaft bolts. Make sure you torque the nut to the specifications for the.

From www.extremeterrain.com

Jeep Wrangler JK Suspension Torque Specs Jeep Jk Drive Shaft Torque Specs Web with a torque wrench tighten the nut to 160 ft lbs of torque. We called the dealer and they said. All other drive shaft bolts. Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. For most of the screws they. Web 88 rows these torque. Jeep Jk Drive Shaft Torque Specs.

From repairengineoliver99.z19.web.core.windows.net

Jeep Wrangler Drive Shaft Replacement Jeep Jk Drive Shaft Torque Specs Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. If nut is not tight enough you could have some vibration. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or.. Jeep Jk Drive Shaft Torque Specs.

From www.quadratec.com

Rough Country 5072.1 Rear CV Drive Shaft for 1218 Jeep Wrangler JK Jeep Jk Drive Shaft Torque Specs Web apply some loctite to the nut threads and install the center nut on the flange. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. If nut is not tight enough you could have some vibration. Make sure you torque the nut to. Jeep Jk Drive Shaft Torque Specs.

From jsmithmoore.com

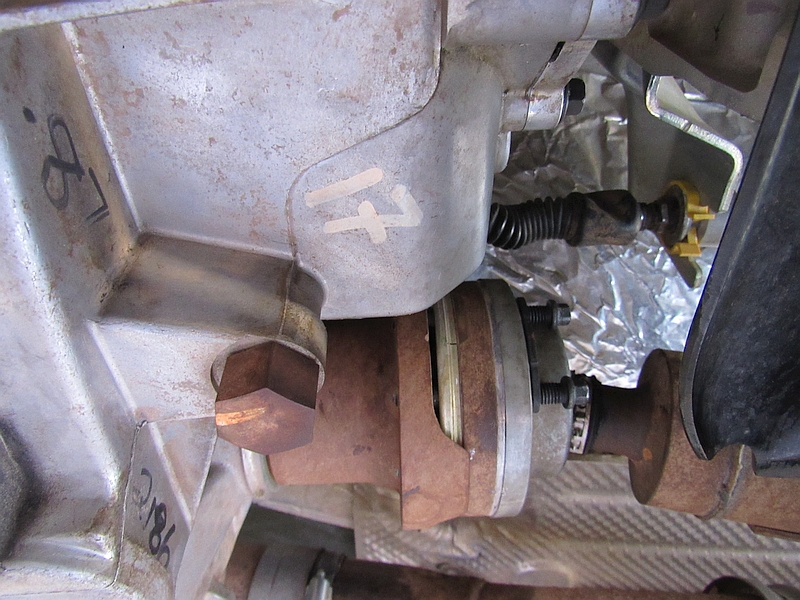

Jeep jk differential torque specs Jeep Jk Drive Shaft Torque Specs All other drive shaft bolts. For most of the screws they. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. We called the dealer and they said. Make sure you torque the nut to the specifications for the. Web with a torque wrench. Jeep Jk Drive Shaft Torque Specs.

From americanprime.com.br

Jeep Jk Engine Torque Specs Quick Delivery Jeep Jk Drive Shaft Torque Specs Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. We called the dealer and they said. All other drive shaft bolts. If nut is not tight enough you could have some vibration. Web 88 rows these torque specs cover all of the important. Jeep Jk Drive Shaft Torque Specs.

From genright.com

Jeep Wrangler Driveshaft Jeep JK Drive Shaft Kit GenRight Jeep Parts Jeep Jk Drive Shaft Torque Specs For most of the screws they. Web with a torque wrench tighten the nut to 160 ft lbs of torque. Web apply some loctite to the nut threads and install the center nut on the flange. All other drive shaft bolts. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. Make sure. Jeep Jk Drive Shaft Torque Specs.

From www.quadratec.com

Jeep Wrangler JK Front Drive Shaft Parts Quadratec Jeep Jk Drive Shaft Torque Specs We called the dealer and they said. For most of the screws they. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. Make sure you torque the nut to the specifications for the. If nut is not tight enough you could have some. Jeep Jk Drive Shaft Torque Specs.

From www.quadratec.com

Yukon Gear & Axle 1310 HD Rear Drive Shaft for 0718 Jeep Wrangler JK 2 Jeep Jk Drive Shaft Torque Specs Web with a torque wrench tighten the nut to 160 ft lbs of torque. Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. If nut is not tight enough. Jeep Jk Drive Shaft Torque Specs.

From dolly-blaustein.blogspot.com

jeep jk front drive shaft replacement dollyblaustein Jeep Jk Drive Shaft Torque Specs Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. For most of the screws they. Web apply some loctite to the nut threads and install the center nut on the flange. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that. Jeep Jk Drive Shaft Torque Specs.

From www.vividracing.com

Rubicon Express Drive Shaft Package for 1217 Jeep JK Wrangler Jeep Jk Drive Shaft Torque Specs If nut is not tight enough you could have some vibration. Web apply some loctite to the nut threads and install the center nut on the flange. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. All other drive shaft bolts. Web i'm. Jeep Jk Drive Shaft Torque Specs.

From www.quadratec.com

J.E. Reel 3512JK24FM Heavy Duty 1350 Rear Drive Shaft for 1218 Jeep Jeep Jk Drive Shaft Torque Specs Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. Web with a torque wrench tighten the nut to 160 ft lbs of torque. Web i'm installing. Jeep Jk Drive Shaft Torque Specs.

From www.quadratec.com

Tom Woods Front 1350 Drive Shaft for 0718 Jeep Wrangler JK Quadratec Jeep Jk Drive Shaft Torque Specs Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. Make sure you torque the nut to the specifications for the. Web apply some loctite to the nut threads and. Jeep Jk Drive Shaft Torque Specs.

From oliversdriveshaft.com

Jeep™ JKU 4 Door Rear 1350 Rear DriveShaft Rock Crawler Oliver's Jeep Jk Drive Shaft Torque Specs We called the dealer and they said. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. If nut is not tight enough you could have some vibration. Make sure you torque the nut to the specifications for the. Web as a part of routine maintenance or anytime that you work on your. Jeep Jk Drive Shaft Torque Specs.

From www.quadratec.com

Dana Spicer 1310 Series Front Drive Shaft for 0715 Jeep Wrangler JK Jeep Jk Drive Shaft Torque Specs We called the dealer and they said. If nut is not tight enough you could have some vibration. Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts from the driveshaft to the pinion. Web with a torque wrench tighten the nut to 160 ft lbs of torque. For most of the screws. Jeep Jk Drive Shaft Torque Specs.

From somarmotor.com

Front Drive Shaft 20072016 Jeep Wrangler JK & Wrangler Unlimited JK Jeep Jk Drive Shaft Torque Specs If nut is not tight enough you could have some vibration. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. Make sure you torque the nut to the specifications for the. For most of the screws they. Web with a torque wrench tighten. Jeep Jk Drive Shaft Torque Specs.

From www.youtube.com

Jeep JK/JKU Driveshaft Advice, Replacement and DO's and DON'T's! YouTube Jeep Jk Drive Shaft Torque Specs If nut is not tight enough you could have some vibration. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. Web apply some loctite to the nut threads and install the center nut on the flange. All other drive shaft bolts. For most of the screws they. Web with a torque wrench. Jeep Jk Drive Shaft Torque Specs.

From www.differentials.com

Jeep Axle Shafts Jeep Rear Axles West Coast Differentials Jeep Jk Drive Shaft Torque Specs We called the dealer and they said. Web apply some loctite to the nut threads and install the center nut on the flange. For most of the screws they. Web with a torque wrench tighten the nut to 160 ft lbs of torque. Web i'm installing a regeared axle and i've got all the torque specs except the smallish bolts. Jeep Jk Drive Shaft Torque Specs.

From www.quadratec.com

Yukon Gear & Axle 1310 OE Rear Drive Shaft for 0718 Jeep Wrangler JK 2 Jeep Jk Drive Shaft Torque Specs All other drive shaft bolts. Web as a part of routine maintenance or anytime that you work on your jeep jk wrangler, it is important that you tighten any bolt and/or. Web 88 rows these torque specs cover all of the important components of your wrangler’s a/c system. We called the dealer and they said. Web apply some loctite to. Jeep Jk Drive Shaft Torque Specs.